1. Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket

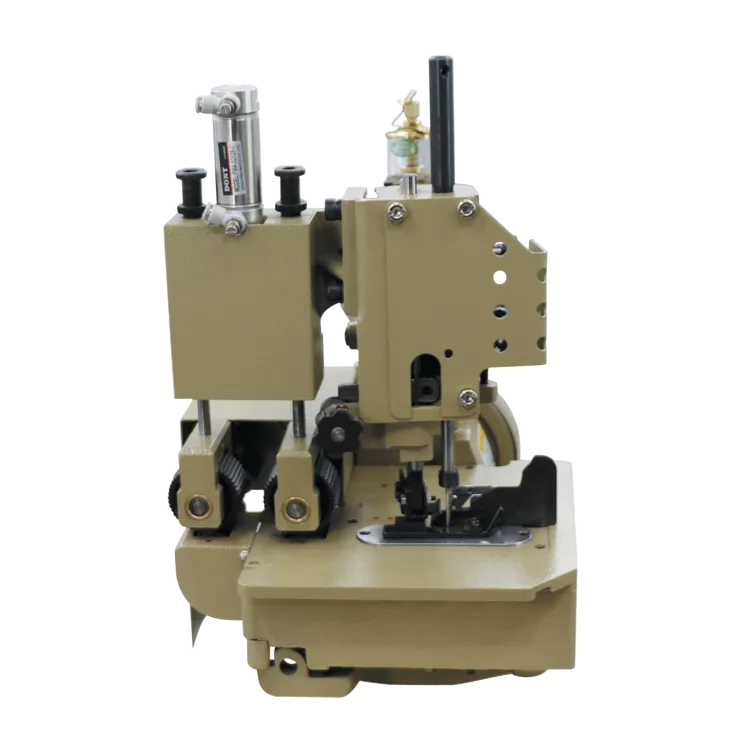

The Importance of Industrial Bag Closing Machine Heads in Modern Manufacturing

The Best Sewing Machines for Upholstery A Comprehensive Guide

- The HD3000 sewing machine is a versatile and durable tool that can handle a wide range of sewing projects with ease. Whether you are a beginner or a seasoned professional, this machine is sure to meet your sewing needs and exceed your expectations.

Ideal for Quilting and Crafting

- 60% stronger motor than standard machines

Investing in a commercial upholstery sewing machine is a crucial step for anyone serious about upholstery work. With the right machine, you can enhance your productivity, improve the quality of your work, and ultimately satisfy your customers. By understanding the features and options available, you can make an informed decision that will serve you well in your upholstery endeavors. Whether you’re a seasoned professional or just starting, the right sewing machine can make all the difference in achieving stunning upholstery results.

- .

A serger, also known as an overlock machine, is an invaluable tool for both professional seamstresses and hobbyists alike. While traditional sewing machines are great for piecing fabrics together, sergers take sewing to another level by finishing edges, preventing fraying, and providing a professional finish that elevates any garment or textile project. Below are several ways you can utilize a serger effectively.

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Conclusion

4. Use Clips Instead of pins, consider using fabric clips to hold thicker layers together while sewing. Clips work better with thicker upholstery materials and provide a strong grip without damaging the fabric.

It's essential to consider your specific needs and budget when evaluating pattern sewing machine prices. Investing in a high-quality machine can lead to long-term savings by reducing maintenance costs and increasing production efficiency.

Using a double needle involves a few critical steps to ensure proper functionality. First, it is essential to select the right type of needle for the fabric being used. Double needles come in various sizes and distances between the needle points, which correspond to different applications. For example, a narrower spacing is suitable for delicate fabrics, while wider spacing works well for more durable materials.

Conclusion

Another significant benefit of twin needle sewing is its ability to reduce stitching time and improve efficiency. For those who work on larger projects or produce items in bulk, this technique allows for two lines of stitching to be completed at once, effectively cutting down on the time spent sewing. This time-saving benefit can be particularly valuable in a professional setting where meeting deadlines is crucial.

In the realm of textile production, efficiency, precision, and creativity are paramount. Among the tools that have transformed this industry, the industrial zig zag embroidery machine stands out for its versatility and capability to produce intricate designs with ease. This article explores the features, benefits, and applications of these advanced machines, which are becoming indispensable in modern garment manufacturing.

A Brief History

Preparing Your Sewing Machine

Intended Purpose

The Evolution and Impact of CNC Programmable Sewing Machines in Modern Textile Manufacturing

1. Choose the Right Needle It is essential to select the appropriate needle for sewing leather. Leather needles are specifically designed with a wedge-shaped tip to penetrate the material without causing damage.

Applications

Sewing Challenges and Tips

Sewing Machines for Leather Jacket Production A Comprehensive Guide

Known for its reliability, the Janome HD3000 is a favorite among seasoned sewists. This machine offers 18 built-in stitches, a one-step buttonhole, and a solid aluminum body that enhances its sturdiness. The HD3000 has a unique needle threading system, which simplifies the process, reducing frustration for beginners and experienced crafters alike. Additionally, its drop feed setting makes this machine suitable for free-motion sewing and quilting, expanding its versatility.

what are heavy duty sewing machines used for

In the realm of industrial manufacturing, efficiency and precision are paramount. Among the myriad of machines that contribute to the production process, the PP (Polypropylene) bag stitching machine plays a vital role in the packaging industry. As the demand for durable and versatile packaging solutions continues to rise, understanding the functionality, evolution, and significance of PP bag stitching machines is crucial.

The Benefits of Cylinder Bed Sewing Machines

To ensure the overlock machine rate remains competitive, manufacturers can take several steps

Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket

Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket Choose the Right Butterfly Screws Make sure to select butterfly screws that are appropriate for your TV mount and bracket